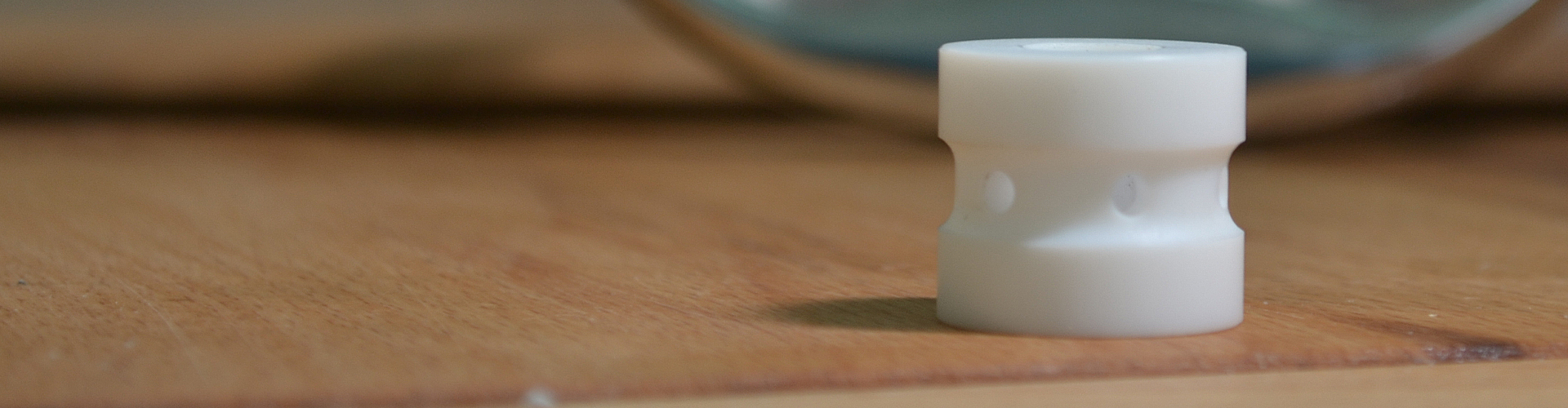

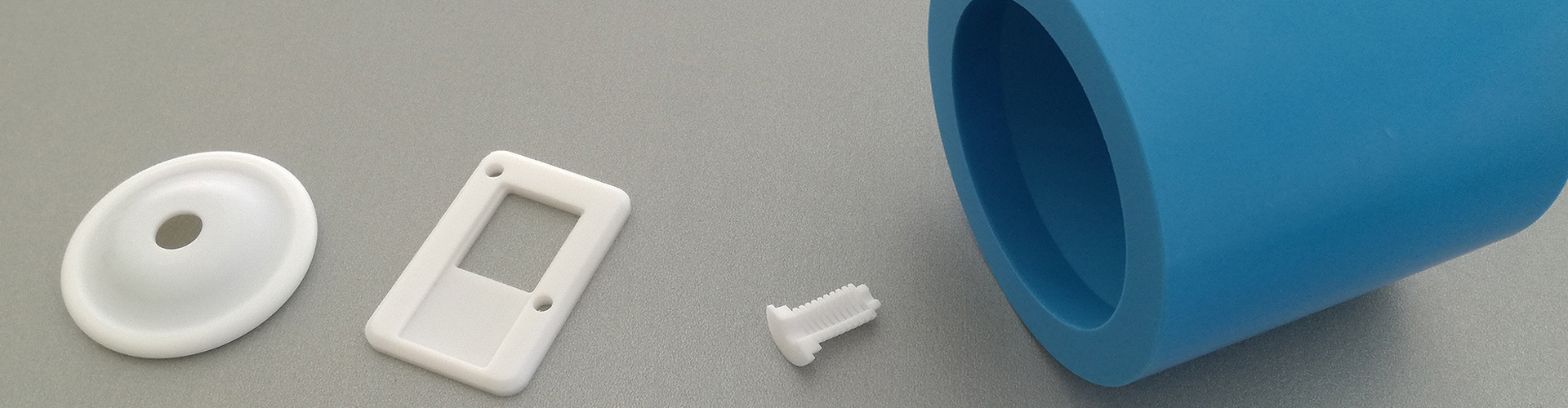

CNC machining of PTFE and PTFE compounds.

PTFE has countless benefits, but at the same time, it also has some disadvantages. These can be overcome by LOADING the PTFE with COMPOUNDS such as BRONZE, GRAPHITE CARBON, FIBERGLASS, PEEK, EKONOL, or STAINLESS STEEL, to name a few compounds that substantially improve the characteristics of VIRGIN PTFE. These compounds are loaded into the powder, and we transform it to create the bars, tubes, or plates we need for our machined parts in PTFE with COMPOUNDS. By controlling the entire process from the powder, we ensure complete product traceability and the ability to achieve tight tolerances in our machining due to our compression molding process, which is much more advantageous than the extrusion process for obtaining critical tolerances. At MP NEOCOMPOSITES, we will develop your product in PTFE or PTFE LOADED with the level of exigency you require.

Menú

Menú